In the manufacturing sector, authoring work instructions is no simple task.

Many considerations go into writing work instructions, all of which are timely and impact the productivity of the entire operation. The entire process is tedious. And once the instructions are completed, they are often inefficient and require rework.

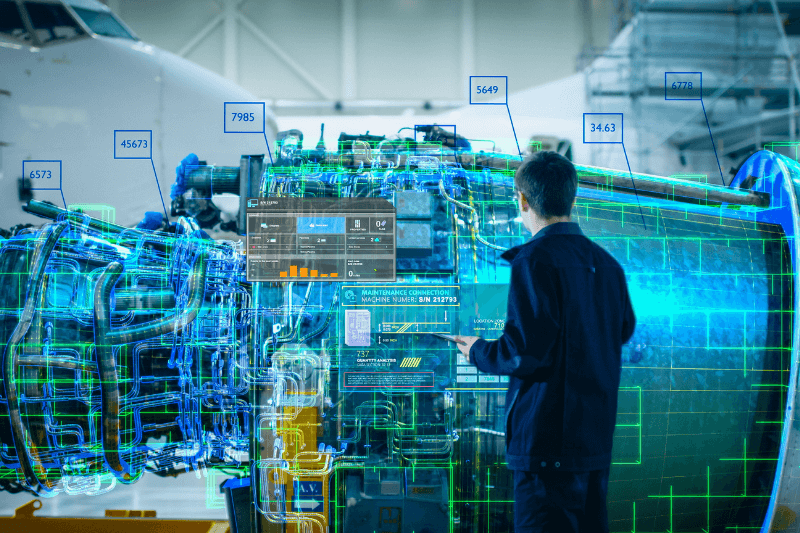

With the evolution of technology through Industry 4.0, it should be expected that our most universal issues are addressed. Luckily, augmented reality (AR) has changed the way we write work instructions, making it easier through visual and auditory cues, broadening mindwidth, and creating more intuitive and scalable programs.

In This Article

- The Challenges of Writing Work Instructions

- How AR Transforms Text Instructions Into Visual Cues

- Enterprise AR Saves Mindwidth

- AR Work Instructions are Intuitive and Scalable

The Challenges of Writing Work Instructions

Even the simplest procedures can require pages and pages of detailed instructions. To assemble a single part, an engineer will spend hours writing out – in full detail – each step of the process, ensuring the verbiage used is easily understandable to an operator carrying out the task to avoid confusion.

Then the work instructions may even undergo a graphic design phase – often carried out by an engineer and taking several more hours to complete. Depending on the sophistication of resources available, these illustrations can be crudely made and tough to decipher.

And what happens if you need clarification on how to complete a specific step for a certain part? There is a library of instruction manuals, with dozens of serial-numbered, dust-clad binders until you find the correct part, and leaf through the pages to find instructions for the right step in the process. Good luck reaching your productivity goals!

Writing work instructions is an iterative process. Once created, they must be constantly monitored and updated as changes are made. If an operator is used to doing things a certain way and the process suddenly changes without effective communication of new work instructions, there will be an instant quality defect.

Clearly, this traditional method of writing (and utilizing) manufacturing work instructions is outdated and grossly inefficient – both in terms of time and money. Manufacturing organizations are now utilizing augmented reality to address these issues.

AR Transforms Text Instructions Into Visual Cues

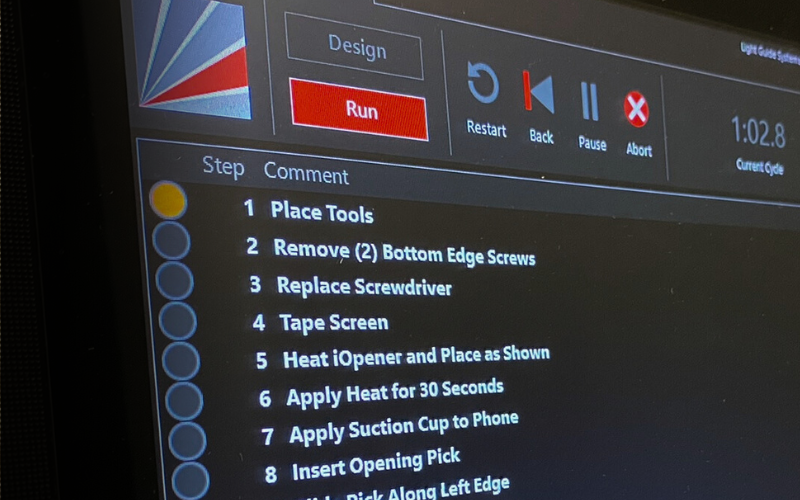

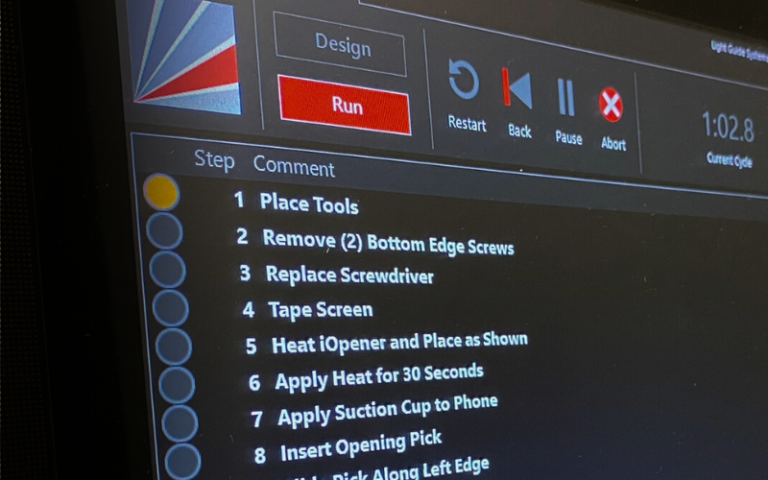

AR technology, like LightGuide, allows manufacturing organizations to distill pages upon pages of complex work instructions into a hyper-efficient, visual, and easy-to-understand process.

Complete with audio and visual prompts, pacing, and direction, operators are guided through every step of a manual process. All they have to do is follow the lights!

This emphasis on making work instructions visual is especially valuable for international manufacturing companies with multiple facilities in different countries. Work instructions written in the United States can be effortlessly adapted at plants in Mexico, Germany, or China, ensuring a consistent standardization of assembly processes across global operations.

Take a closer look at LightGuide projected AR work instructions

Enterprise AR Saves Mindwidth

Here at LightGuide, we refer to ‘mindwidth’ as bandwidth for your mind – the amount of mental energy required for manufacturing operators to learn and repeat work instructions.

Augmented reality tools save valuable mindwidth by visually displaying work instructions directly onto a manufacturing work surface and guiding operators through the process step by step, thus eliminating the need to read through instruction manuals and memorize multiple processes.

The adoption of AR technology in this manner results in much faster training periods for new hires, improved product quality, diminished assembly times, and higher returns.

AR Work Instructions Are Intuitive and Scalable

Our augmented reality solution is so easy to use that all operators need to do is bring their parts to the workstation, scan the barcode and receive their respective work instructions.

The graphics displayed with AR technology are incredibly intuitive. If an operator is having trouble assembling a part, for example, they can simply project a step-by-step video onto their worktable. Advanced software even allows operators to make modifications on the fly, for things like noting quality alerts to the rest of the staff.

With the help of augmented reality, companies can now use practical augmented reality tools to simplify the process of authoring work instructions, improve employee productivity, and power an efficient factory of the future.

Experience the power of the LightGuide AR platform

To find out more about using AR to write work instructions, please contact us or request a demo.

Ready to Explore How Projected AR Work Instructions Can Give Your Workforce a Competitive Advantage?

Connect with our team to see how the LightGuide platform can transform your operations.