The Future of Manufacturing: AR Work Instructions

In the dynamic world of manufacturing, the transition from traditional to digital work instructions marked a pivotal shift toward enhanced efficiency and accuracy. LightGuide projected AR work instructions go beyond screens and manuals, creating a truly immersive experience where workers are empowered with real-time visual guidance projected directly on their workspace.

Trusted by the World’s Most Innovative Companies

|

|

|

|

|

|

|

|

|

|

|

|

The Power of Going Paperless with Digital Work Instructions

Digital work instructions streamline the implementation of processes and procedures, leading the way to a new era of paperless manufacturing. Including step-by-step instructions combined with text, images, videos, and other interactive elements, they are far more effective than static documents.

Discover why a paperless manufacturing environment powered by digital workflows is superior:

Why Projected AR is the Future of Digital Work Instructions

Unlike traditional digital methods involving monitors or mobile devices, LightGuide projected AR technology marks a significant leap forward. Say goodbye to the limitations of outdated manuals and the confines of small device screens. LightGuide’s projected AR system doesn’t just deliver immersive, real-time instructions, it seamlessly integrates with your factory tools to revolutionize the way your team works.

Explore how projected AR work instructions can optimize your paperless manufacturing processes:

Enhance Focus and Engagement

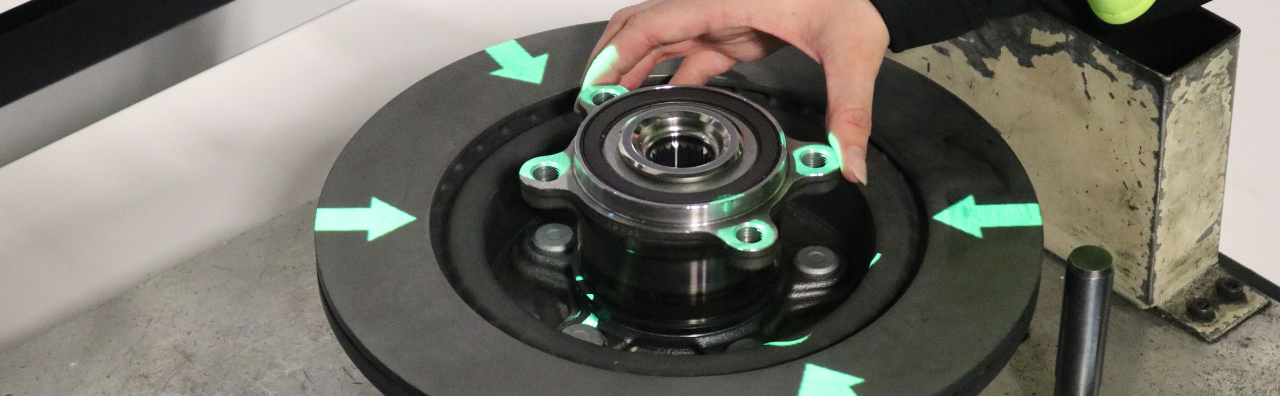

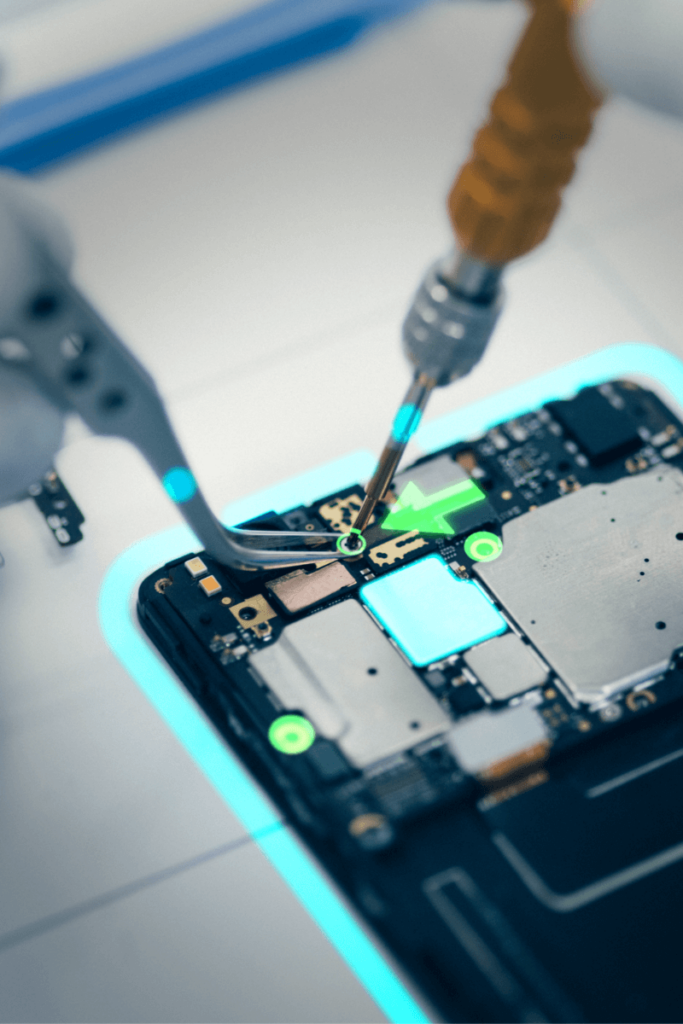

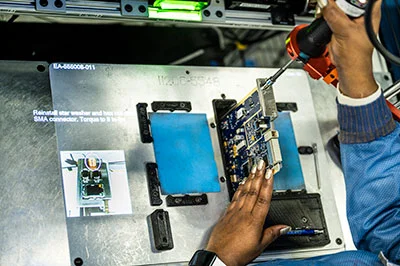

Heads-down, hands-free guidance: Instructions, schematics, and other critical information are directly projected onto work surfaces, keeping workers focused and engaged, without distractions.

Master Complex Tasks with Confidence

Eliminate confusion, increase understanding, and boost confidence for even the most complex tasks through step-by-step AR guidance.

Comfort and Practicality

Unlike wearable AR devices, projected AR ensures comfort throughout the day without the need for battery recharging, making it ideal for prolonged use in manufacturing settings.

Enterprise-Ready Integration

Integrate seamlessly and securely with factory smart tools, vision cameras, and 3D sensors for real-time operator feedback, guidance, and confirmation.

Always-On Reliability

Projected AR systems are durable, line-powered, and do not use batteries; they never require charging and support 24/7 factory environments, making it an industrial-grade solution robust enough to operate in the toughest manufacturing environments.

Increased Safety

Projected AR can include safety warnings or highlight hazardous areas directly on the work surface, significantly improving workplace safety.

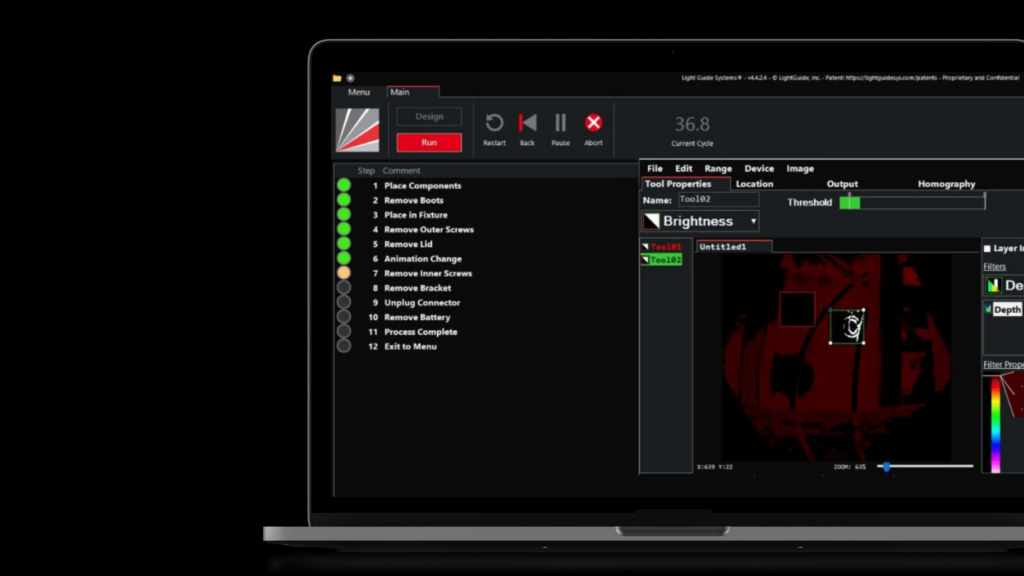

Edit Work Instructions Visually

LightGuide AR Delivers Proven Results

- 90%+ Quality Improvement

- 70%+ Training Efficiency

- 50%+ Productivity Increase

Video Player Anchor

Why LightGuide is the Leader in Projected AR Work Instructions

Optimize SOPs, Prevent Errors, and Boost Efficiency in Real-Time

Envision a workplace where interactive digital AR work instructions seamlessly align with your SOPs, detecting, and correcting, errors instantly. This not only accelerates cycle times but increases quality significantly.

Discover how LightGuide sets your operations apart in the competitive landscape of manufacturing:

Next-Level Operational Efficiency

Streamline manufacturing SOPs with immersive, projected AR work instructions for hands-free, real-time guidance.

Enhanced Accuracy and Comprehension

Enhance accuracy and comprehension with intuitive, image-rich visuals displayed directly on work surfaces.

Efficient Training and Fewer Errors

Reduce training time and errors through easily duplicated step-by-step AR work instructions that bring your operator up to standard from day one.

Dynamic On-the-Job Learning

Facilitate on-the-job learning with dynamic, AR-enhanced SOPs adapting to worker pace.

Enhanced Monitoring and Control

Improve managerial oversight for SOP adherence, quality assurance, and maintenance activities with digital traceability and real-time analytics.

Comprehensive Knowledge Management

Create a complete knowledge base holding all your factory’s standard operating procedures.

Achieve Your Sustainability Goals with Paperless Manufacturing

• Reduce your carbon footprint and save money on paper and printing costs.

• Increase your manufacturing quality to reduce material waste and rework, decreasing environmental impact.

• Streamline training and operations for energy-efficient production.

Featured Customer Case Studies

Leading Aerospace & Defense Manufacturer Eliminates Defects with AR Technology

Industry leader L3Harris must ensure its products adhere to the highest standards of quality and reliability. After implementing LightGuide AR work instructions on a line with 17 variants, the company eliminated defects and changeover per variant.

Tech Insurance Company Transforms Electronics Repair Processes with AR

Using projected AR, this company was able to reduce complexity and standardize repair processes by digitizing workflows and providing technicians with precise visual guidance.

Lightning eMotors Adopts AR Work Instructions for Error-free EV Manufacturing

Lightning eMotors, a leader in EV manufacturing and fleet electrification, decreased cycle time by up to 50% and reduced training time by 75% using LightGuide AR work instructions.

Testimonials

"[LightGuide] reduces the reliance on operator memory – also known as “cognitive ergonomics” – effectively turning a complex process with multiple steps into a series of simple processes with single steps."