Trusted by the World’s Most Innovative Companies

|

|

|

|

|

|

|

|

|

|

|

|

A Practical and Proven Digital Work Instruction Platform to Resolve Your Manufacturing Challenges

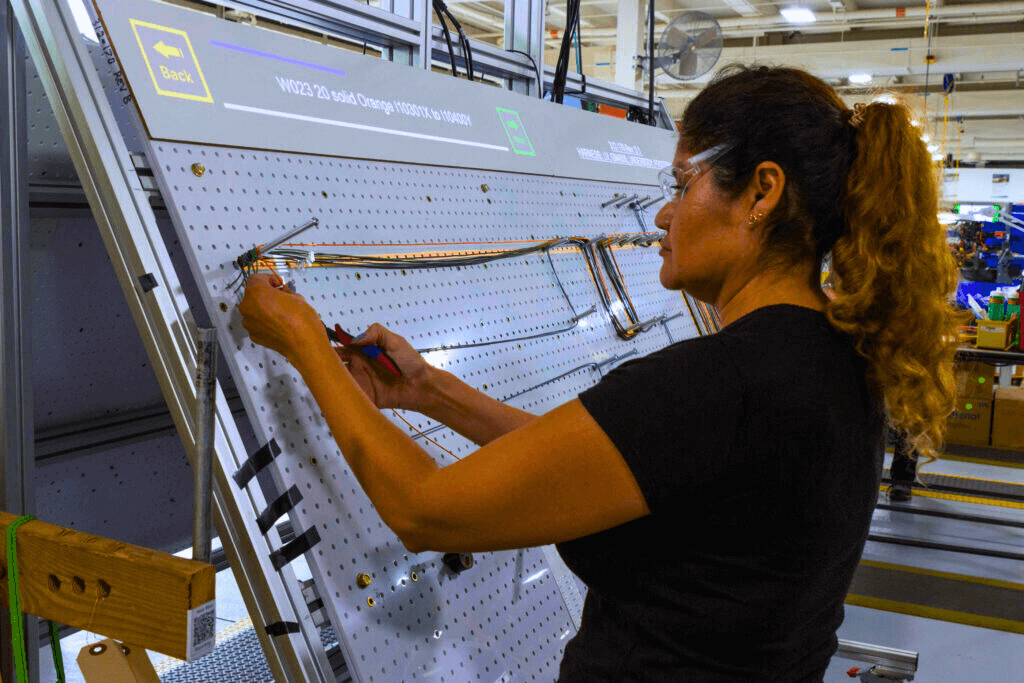

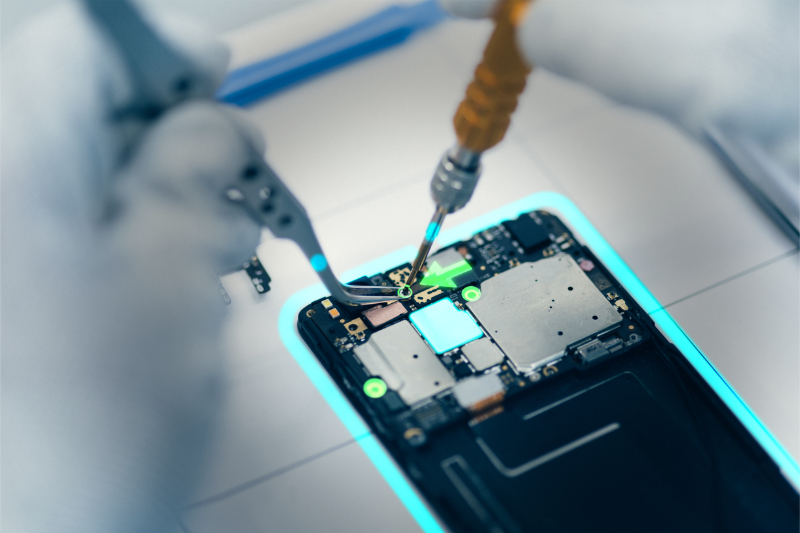

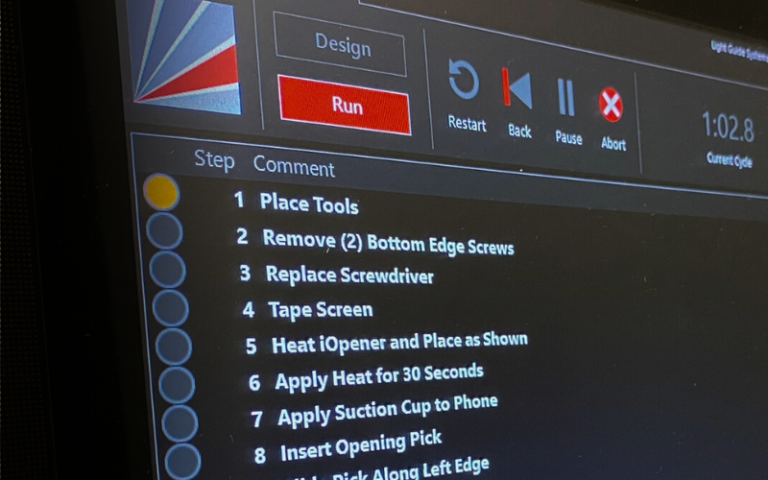

LightGuide’s augmented reality (AR) software transforms manual processes by projecting digital step-by-step work instructions onto an employee’s work surface, standardizing and error-proofing the work. Coupled with 3D sensors and vision cameras, the system prevents and detects errors in real-time while capturing data and insights on your operator’s performance and quality.

Video Player Anchor

See LightGuide AR Work Instructions in Action

LightGuide digital work instructions help businesses overcome their most complex manufacturing and operational challenges by automating complex manual processes.

Zero Defect Manufacturing Made Simple

Easily configured, customized, and programmed by your team, LightGuide digitizes complex frontline processes and replaces paper or monitor-based work instructions with projected AR work instructions. It connects seamlessly with your existing factory systems using pre-built digital connectors to hundreds of different MES, PLC, torque tools, cameras, and sensors.

LightGuide Digital Work Instructions: Proven Results

- >90% Improve Quality

- >50% Increase Throughput

- >30% Accelerate Training

Your Guide to AR Applications on the Factory Floor

Not all types of augmented reality are created equal. Use this guide to discover which type of industrial AR is best suited for your factory application, learn from real-world case studies, and more.

|

|

AR Work Instructions for Every Application

From small form factor training to complex, multi-station workcell assembly, there is a LightGuide digital work instruction solution for virtually any application.

LightGuide smartAR™ Desktop

The smartAR Desktop is an all-in-one system for AR work instructions, training and more.

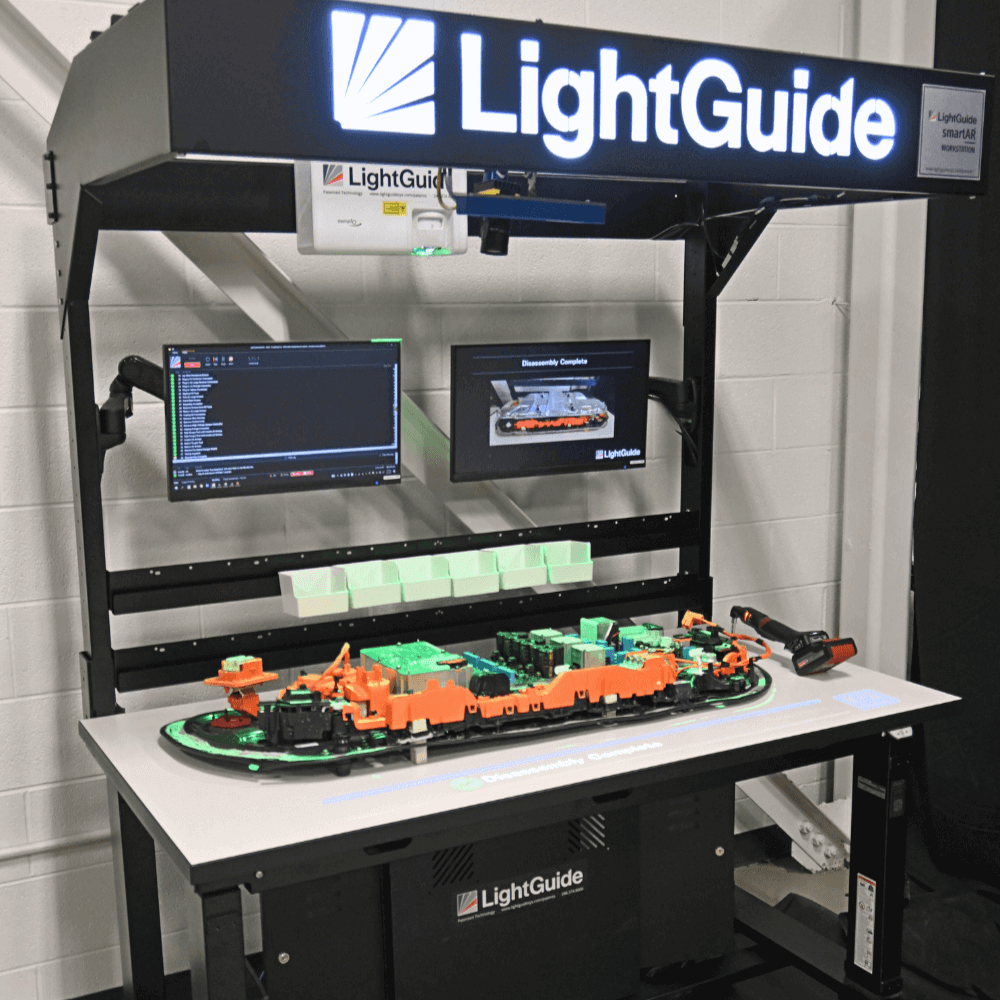

LightGuide smartAR™ Workstation

The smartAR Workstation is an industrial-grade AR system for error-free assembly, inspection and training.

LightGuide smartAR™ Workcell

The smartAR Workcell is a scalable platform supporting the largest and most complex manual industrial applications.

Our Global Network of Enterprise Technology Partners

|

|

|

|

|

|

Featured Customer Case Studies

Leading Aerospace & Defense Manufacturer Eliminates Defects with AR Technology

Industry leader L3Harris must ensure its products adhere to the highest standards of quality and reliability. After implementing LightGuide AR work instructions on a line with 17 variants, the company eliminated defects and changeover per variant.

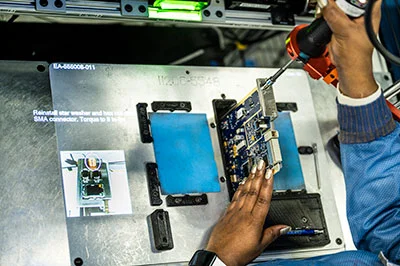

Tech Insurance Company Transforms Electronics Repair Processes with AR

Using projected AR, this company was able to reduce complexity and standardize repair processes by digitizing workflows and providing technicians with precise visual guidance.

Lightning eMotors Adopts AR Work Instructions for Error-free EV Manufacturing

Lightning eMotors, a leader in EV manufacturing and fleet electrification, decreased cycle time by up to 50% and reduced training time by 75% using LightGuide AR work instructions.

What our Customers are Saying

Testimonials

"[LightGuide] reduces the reliance on operator memory – also known as “cognitive ergonomics” – effectively turning a complex process with multiple steps into a series of simple processes with single steps."

Discover More Industrial Augmented Reality Resources

Benefits of AR Work Instructions for Automotive Manufacturing

As automotive manufacturing becomes more complex, companies are challenged to maintain and improve quality while also increasing productivity to reduce costs.

6 Uses of AR for Manufacturing In Every Industry

Discover how enterprises are using AR-powered digital work instructions to solve their manufacturing challenges in training, standardization, optimization, and worker well-being.

The Future of Electronics Repair: How AR is Transforming Tech Support

Discover how companies are gaining a competitive advantage by using AR work instructions to facilitate faster, safer, and more reliable electronics repair services.

Ready to Put the Power of AR Work Instructions to Work for You?

Connect with our team to see how LightGuide digital work instructions can transform your operations.