The Rise of the Smart AR Warehouse: How Augmented Reality is Transforming Warehousing and Intralogistics

Welcome to the future of smart warehousing, where projected augmented reality (AR) is revolutionizing logistics operations. In today’s fast-paced, on-demand economy, warehouses face unprecedented challenges, including escalating order volumes, accelerated delivery demands, and a growing scarcity of skilled labor. To navigate these challenges and stay ahead, warehouses must embrace innovation.

Projected AR stands out as a game-changing technology. Unlike traditional AR, which relies on headsets, glasses, or handheld devices, projection-based AR overlays digital information directly onto the physical warehouse environment. This ergonomic and hands-free approach transforms traditional logistics processes, enhancing efficiency, accuracy, and worker empowerment.

→ Free Download: Your Guide to Warehouse Augmented Reality [Access Now]

IN THIS ARTICLE:

Benefits of Warehouse Augmented Reality

LightGuide SpotGuideAR: An Augmented Reality Warehouse System

Next-Level Warehouse Solutions with AR and ProGlove Integration

The Vision for the Future of Smart AR Warehouses

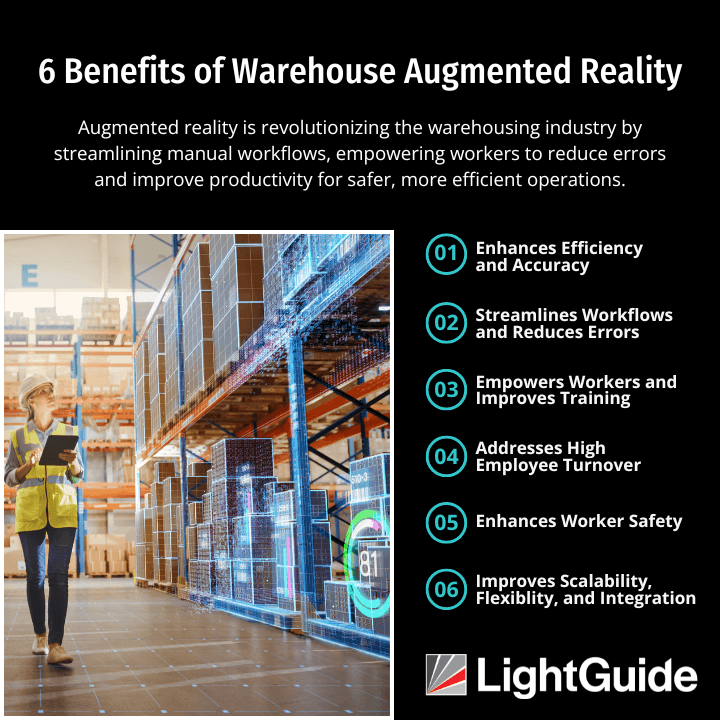

6 Benefits of Warehouse Augmented Reality

Augmented reality is revolutionizing the warehousing industry by streamlining manual workflows and empowering workers to reduce errors and improve productivity.

Let’s explore how AR tackles these challenges to improve intralogistics and create safer, more efficient warehouse operations.

RELATED CONTENT: What is Intralogistics and Why is it Important for Smart Warehousing?

#1: AR Enhances Warehouse Efficiency and Accuracy

Projected AR brings a new dimension to warehouse efficiency and accuracy. By overlaying crucial information directly onto the physical environment, it eliminates the need for traditional methods that slow down operations.

Imagine workers navigating warehouses easily, thanks to optimized picking routes and visual cues that pinpoint the exact location of each item. Warehouse AR empowers workers with the knowledge needed for efficient order fulfillment, including information on order quantities and inventory levels.

This real-time guidance drastically reduces the time it takes to stow, locate, pick, pack, and stage products for shipping. Research from DHL reports that augmented reality picking sped up the process and reduced errors, improving efficiency by 25%.

- Optimized Picking Routes: Warehouse AR guides workers along the most efficient picking routes, significantly reducing travel time. According to Logiwa, picking accounts for 50% of a warehouse’s labor efforts. Augmented reality warehouse picking speeds up this process and boosts productivity.

- Personalized Experiences: AR can offer personalized experiences for each worker and adjust the language or complexity of instructions based on their preferences or experience level.

#2: AR Streamlines Warehouse Workflows and Reduces Errors

Warehouse AR goes beyond simply displaying information. Its true power lies in optimizing workflows, leading to more efficient operations.

- Real-Time Inventory Management: Live updates on inventory levels, expiration dates, or reorder alerts can be displayed directly on storage bins or pallets. According to a study by Zebra, reducing stock-outs and overstock can lower inventory costs by 10%.

- Error-Proofing: As workers approach a picking location, AR highlights the exact item they need, along with quantities and handling instructions. Warehouse AR systems that integrate with vision cameras and sensors can also confirm the accuracy of each pick. This eliminates the need for manual scanning or paper pick lists, ensuring accurate selection of the right products in the right quantities. This reduces errors and speeds up the entire picking process.

- Dynamic Adjustments: The projected information can be dynamically adjusted based on real-time inventory data or worker needs.

#3: AR Empowers Warehouse Workers and Improves Training

Projected AR also makes training more efficient and effective.

The ability to simulate real-world scenarios and provide real-time, on-the-job guidance drastically reduces the learning curve for core warehouse operations.

- Step-by-Step Instructions: Complex tasks can be broken into easy-to-follow steps and projected directly onto the work environment.

- Real-Time Feedback: AR can provide real-time feedback on worker performance and highlight areas for improvement. This real-time guidance can enhance worker performance by 34%, according to a report from the Harvard Business Review.

- Interactive Work Instructions: LightGuide’s AR platform projects interactive work instructions directly onto the work surface, guiding associates step-by-step and preventing errors.

#4: AR Addresses High Employee Turnover

High turnover is a persistent challenge in warehousing. Warehouse and Logistics News reports that warehouse staff turnover is 37% in one year. This is significantly higher than the average turnover rate across all industries of 3.6%. Projection-based AR offers a solution by making training quicker and tasks easier, leading to more satisfied and efficient workers.

- Simplified Complex Tasks: AR can simplify complex warehouse tasks, potentially leading to increased job satisfaction and lower turnover rates. According to The IBM Institute of Business Value, companies using AR have reported a 46% reduction in time to complete tasks.

- Reduced Training Time: New employees can learn picking routes, identify items, and complete tasks accurately with minimal instruction. According to the Society for Human Resource Management (SHRM), effective AR training can cut training time by 50%.

#5: AR Enhances Worker Safety

Projected AR is beneficial for workplace safety, particularly in busy warehouse environments. By clearly defining safe zones for operating machinery and indicating designated standing areas, warehouse AR systems can help prevent accidents and create a safer work environment.

- Safe Zones for Machinery: Projected AR can delineate safe zones around heavy machinery, forklift paths, and other hazardous areas, providing visual cues to keep workers at a safe distance.

- Ergonomic Benefits: By reducing the need for workers to look down at handheld devices or paper lists, projected AR can minimize strain on the neck and eyes. This contributes to a more ergonomic work setup.

- Clear Pathways: AR warehouse systems can highlight efficient and safe walking paths using projected arrows, lines, and other symbols. This helps to avoid collisions and ensure smooth traffic flow within the warehouse.

- Hazard Warnings: Instant alerts for spills, obstructions, or other hazards can be projected directly onto the floor and provide real-time warnings to warehouse workers.

- Hands-Free Operation: Projected AR enables hands-free access to digital information, eliminating the need for monitors, headsets, or handheld devices.

#6: AR Improves Scalability, Flexibility, and Integration

The scalability, flexibility, and integration capabilities of projected AR warehouse systems make them a versatile solution for warehouses of all sizes and types.

- Modular Setups: Warehouse AR systems can be easily adapted to fit different facility sizes and layouts, with multiple projectors interlinked to provide a wide coverage area.

- Seamless Integration: The LightGuide AR platform seamlessly integrates with existing warehouse management systems (WMS), vision cameras, barcode scanners, sensors, and other software to enhance overall operational efficiency.

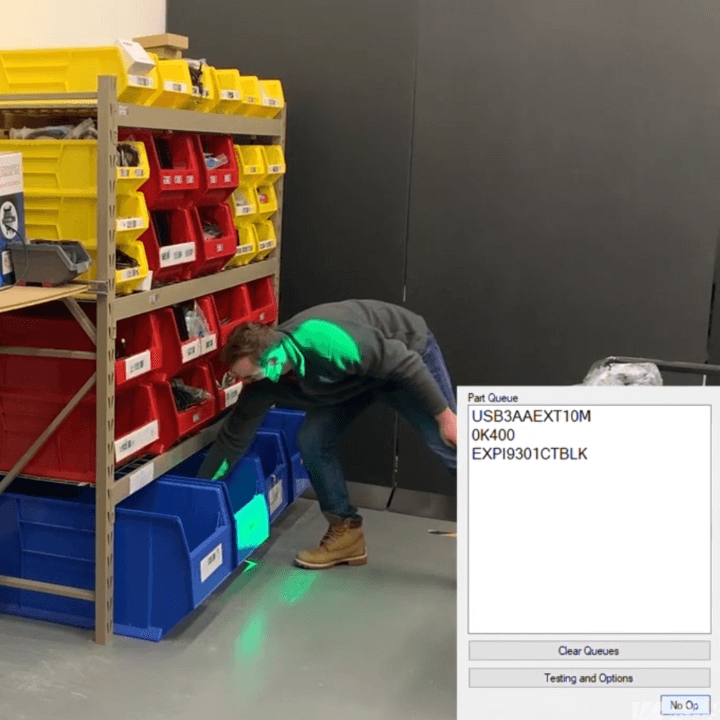

LightGuide SpotGuideAR: An Augmented Reality Warehouse System

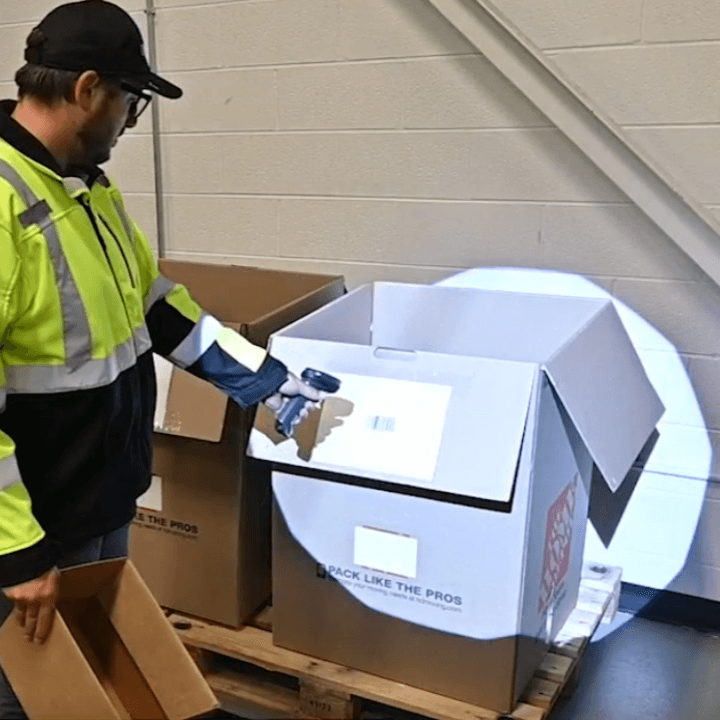

The LightGuide SpotGuideAR platform enhances material handling by utilizing dynamic, programmable spotlight projectors that integrate with factory interfaces. This innovative system guides and organizes materials in real time, providing unmatched accuracy and speed in pick-and-place operations and shipping dock staging.

RELATED CONTENT: Explore the LightGuide SpotGuideAR System for Material Handling

Next-Level AR Warehouse Solutions with LightGuide and ProGlove Integration

LightGuide integrates with ProGlove wearable barcode scanners to streamline material handling processes for fast, accurate fulfillment.

Pairing ProGlove with SpotGuideAR provides an extra edge. Spotlight projection technology visually guides workers to key areas in your warehouse, while ProGlove delivers crucial instructions directly to their hands. This combination dramatically enhances workflow efficiency and accuracy.

- Haptic Feedback: Beyond visual guidance and data, LightGuide communicates with 3D sensors to confirm bin selections and provide haptic feedback via ProGlove wearables. Imagine a subtle vibration from the glove if you reach for the wrong bin. That’s LightGuide preventing errors and optimizing workflows for a truly intelligent warehouse.

- LED Lights: ProGlove features LED lights that provide immediate visual feedback to workers. Green lights indicate a correct scan or action, while red lights signal an error or incorrect action. LightGuide can leverage this instant feedback system to reduce mistakes and improve accuracy.

- LED Screen: The ProGlove wearable includes a small LED screen that displays relevant text and instructions. LightGuide can use this screen to show essential information such as item numbers, bin locations, or next steps in the workflow. Having this information readily available on the glove minimizes the need for workers to check separate devices or paper instructions, thereby speeding up the process.

By leveraging the capabilities of LightGuide projected AR and ProGlove integration, warehouses can empower workers with real-time visual guidance and data directly at their fingertips to create a more efficient and secure working environment.

The Vision for the Future of Smart AR Warehouses

The future of smart warehousing is promising, driven by the advancements in projected augmented reality. As we have explored, this technology is not just a tool but a transformational force that’s reshaping intralogistics from the ground up.

In today’s competitive logistics landscape, agility, efficiency, and accuracy are no longer optional. Projected AR empowers warehouses to achieve these goals, offering a significant competitive advantage.

Information becomes instantly accessible, workflows are optimized, and training is streamlined. The result is a more efficient, accurate, and satisfying work environment. As projected AR continues to evolve and integrate with other technologies, its potential to innovate and transform will only grow, marking a new era in smart warehousing and logistics.

Ready to Revolutionize Your Warehouse with Cutting-Edge AR Technology?

Contact our AR experts today and discover the transformative power of LightGuide.