Asynchronous Headliner Assembly Guided by Augmented Reality

For large-scale assemblies, like headliner assemblies, it’s not uncommon to have more than one operator working on a part asynchronously.

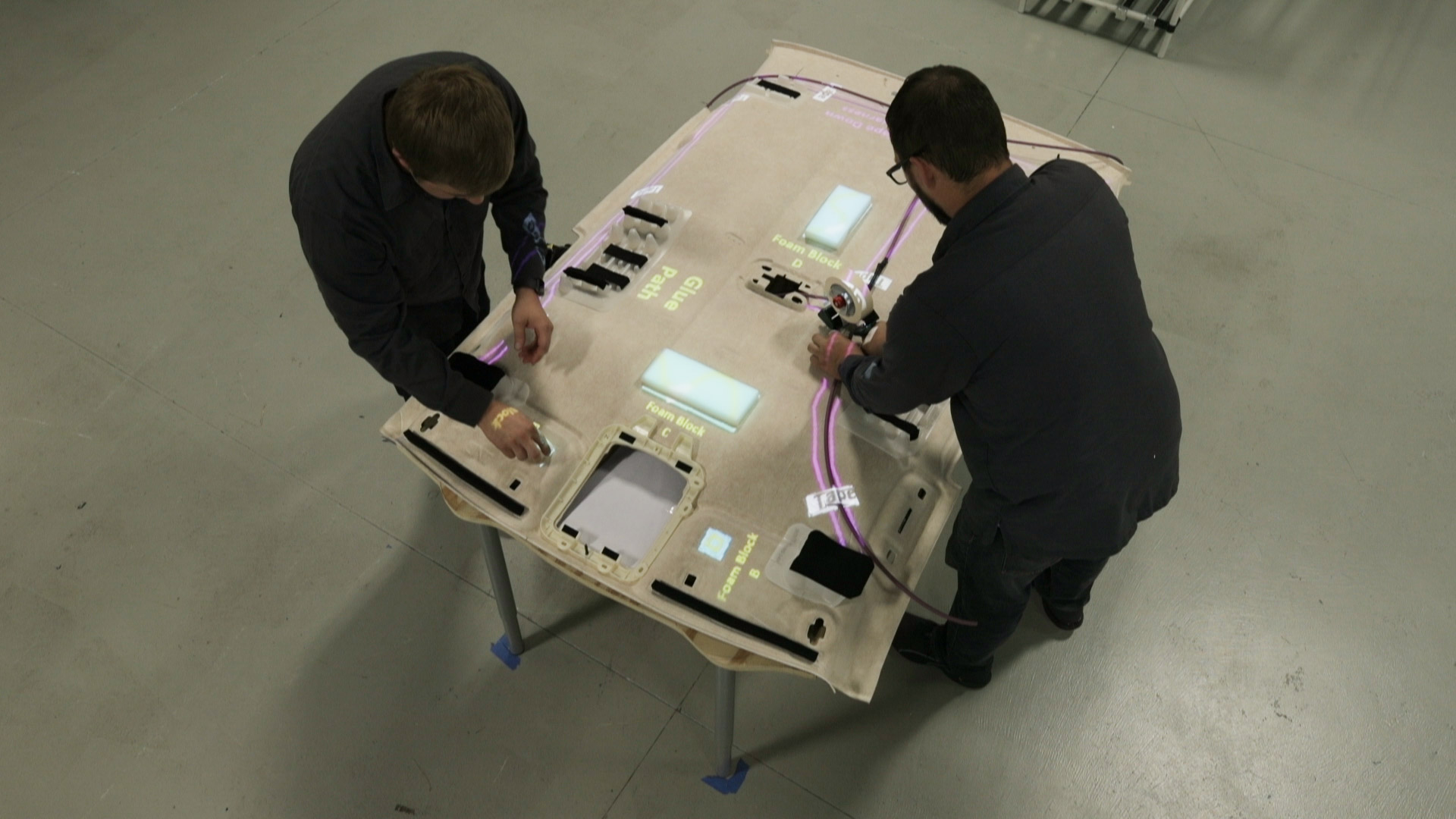

In this video, LightGuide’s industrial augmented reality (AR) work instruction platform projects inspection, paced glue dispensing, and wire harness routing work instructions directly onto an automotive headliner, guiding two operators in an asynchronous team assembly.

AR Guidance for Asynchronous Workflows & Team Assembly

This LightGuide smartAR Workcell is equipped with a ceiling-mounted high-resolution, high-lumen projector that provides real-time AR guidance for an asynchronous headliner assembly. Using 3D sensors, LightGuide can detect when tasks have been completed and advance to the next step in the process.

Because this particular workflow has been created to guide two operators at once, the LightGuide system waits for detection that both operators have completed the step before advancing. The result is that LightGuide can provide asynchronous, dynamic guidance for each step of the headliner assembly workflow.

The Power of Digitizing Manufacturing Workflows with LightGuide

LightGuide’s AR software transforms manual processes by projecting digital step-by-step work instructions onto an employee’s work surface, standardizing and error-proofing the work. Coupled with 3D sensors and vision cameras, the system prevents and detects errors in real time while capturing data and insights on your operator’s performance and quality.

For example, the glue application shown in this video is not only effective for guiding glue placement but also for guiding glue pacing. This ensures glue is applied in the same place, and at the same pace, across every operator and every shift for enhanced quality and throughput.

Related Content:

Precise Manufacturing Work Instructions with Real-Time Torque Data

Projected AR Wire Harness and Cabling Applications

Streamlining Mass Customization in Automotive Manufacturing with Projected AR