For industries like medical, defense, and aerospace, assemblies often need exact replication. Even differences in a millimeter can result in millions of defects that go unnoticed until it’s too late.

Fixturing is one common solution but it still risks minute movement. Businesses need a steadfast, sure method of ensuring precision every time even as production changes.

What is Dynamic Tracking?

Dynamic tracking is the method of identifying an object’s position and providing guidance to an exact location. It functions like a GPS, identifying pathways to the final location and recalculating to adapt to changes.

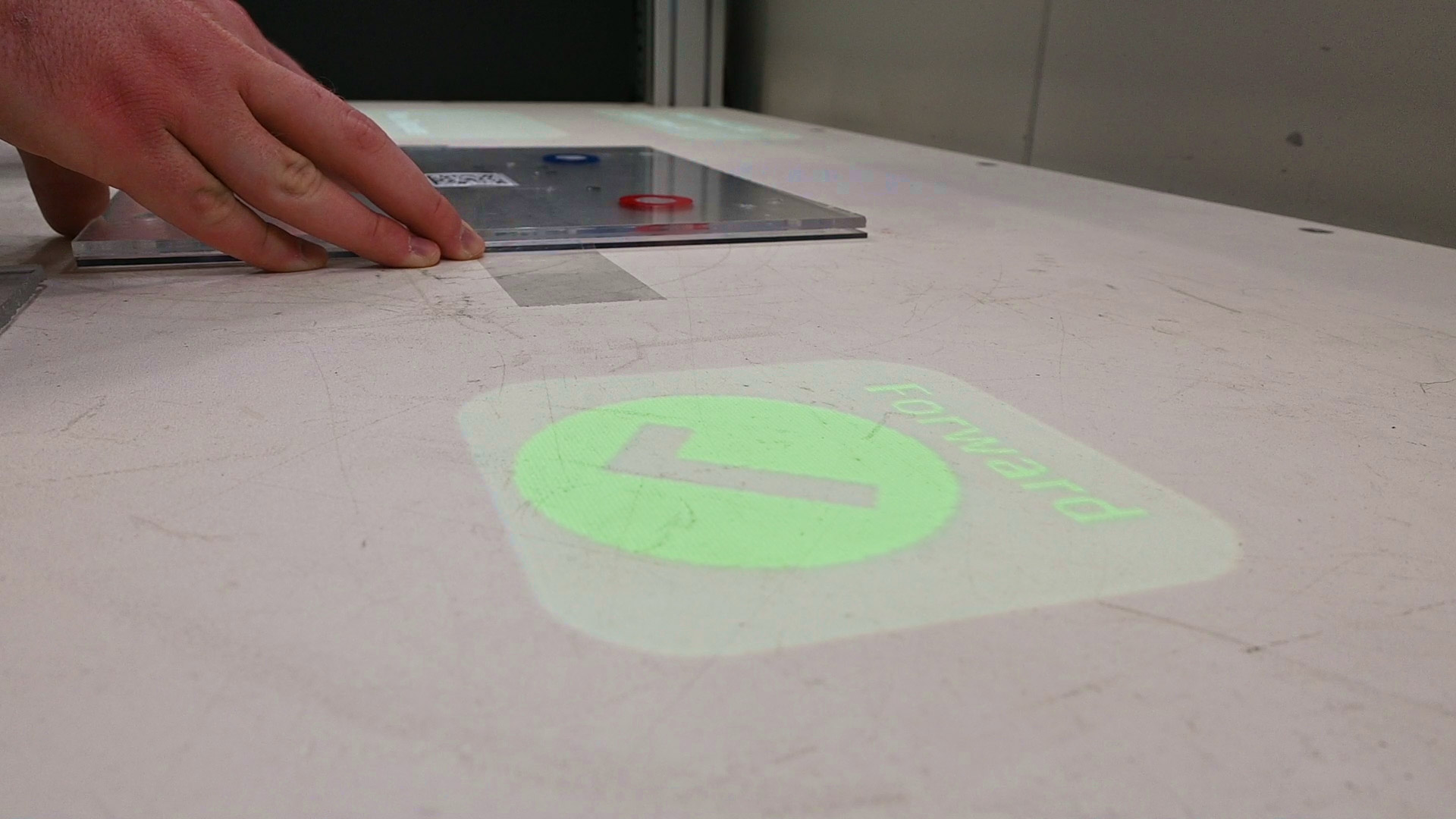

In our “Dynamic Template Tracking” video, you can see an example of dynamic tracking to move a template into position for assembly.

LightGuide creates visual cues to direct the operator to align the plate and provides exact measurements to ensure accuracy.

For the sake of this video, the plate being aligned is clear to show the capabilities of LightGuide and proper alignment to the original plate underneath. In a factory setting, this same programming guides non-transparent parts to accurate alignment as well.

To find out how to use dynamic tracking in your processes, please contact us.